In this era of constant innovations, it becomes essential for steel companies to understand the dynamic industry trends and refine their prevailing business models and portfolios to meet the demands of their end-users. Therefore, to better understand the demands of their end-users and improve workforce efficiency, leading organizations in the steel industry are focusing on employee engagement. With years of expertise in offering employee intelligence services, Infiniti’s insights helps clients implement effective plans to boost workforce efficiency and better understand the needs and wants of their employees.

The Business Challenge

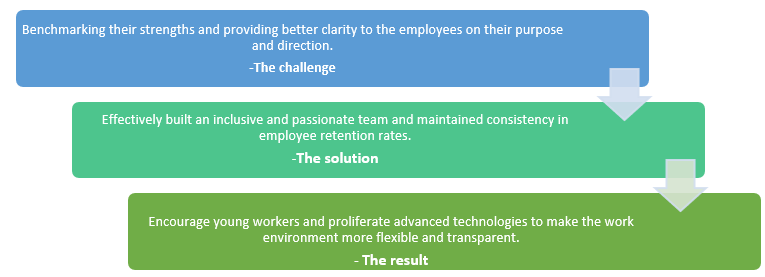

A renowned steel company with branches spread across APAC was facing challenges optimizing their workforce efficiency and providing better clarity to the employees on their purpose and direction. The steel industry client wanted to increase the efficiency of their workforce by better interacting with their employees and understanding their major pain points. Moreover, with the help of this employee engagement study, the steel company wanted to understand the key drivers of engagement and plan activities to bolster employee engagement.

Want more information on our employee engagement solution?

Our Approach and Benefits of the Employee Engagement Solution

To help the steel industry client address challenges pertaining to their workforce efficiency, the employee engagement experts at Infiniti carried out extensive qualitative and quantitative studies and conducted interviews and discussions with prominent stakeholders in the steel industry. Additionally, to benchmark the performance of the steel company, the employee engagement experts at Infiniti also compiled from a wide array of secondary sources such as company presentations, industry journals, paid industry databases, and industry forums and communities.

This employee engagement study helped the steel company understand how to improve the efficiency of their workforce. Additionally, the steel industry client was able to improve their employee retention rate and implement strategic plans to boost their employees’ work efficiency. With the help of this engagement, the steel industry client was also able to implement strategic plans to attract young talent and leverage advanced technologies to make their work environment more engaging.

Additional Benefits of the Employee Engagement Solution

- Helped build a passionate team and devised strategic plans to boost employee retention rates

- Validated surveys and benchmarking tools to assess the employees’ level of engagement

- Implemented strategic plans to improve the work environment

- Efficiently managed the workload and performance and offered a conducive environment to attract and retain diverse workforce