A recent study revealed that a considerable percentage of revenues in the manufacturing organizations is spent on the returns.

The ongoing economic volatility is forcing companies in the transportation space to look for sustainable alternative distribution networks such as reverse logistics. In this competitive space, businesses are looking for effective ways to streamline their supply chain by investing in technology and developing better operational models. In the reverse logistics space, customer satisfaction plays a pivotal role and leading logistic managers are trying to meet the customer’s preferences through easy replacements, refurbishing, and recycling of the sold products. To manage exceptions and better manage the supply, leading businesses in the reverse logistics space need to understand their counterparts and their product offerings. Competitive benchmarking solutions help leading businesses understand their competitors and strategize their inventories to create additional value.

In the retail sector, competitive benchmarking can help reverse logistics providers identify flaws in their offerings and effectively meet the client requirements in terms of repairs, refurbishment, resale, and warranty recovery. Also, leading logistic companies can focus on reverse logistics to reduce costs and address maintenance requirements while meeting customer expectations.

The Business Challenge

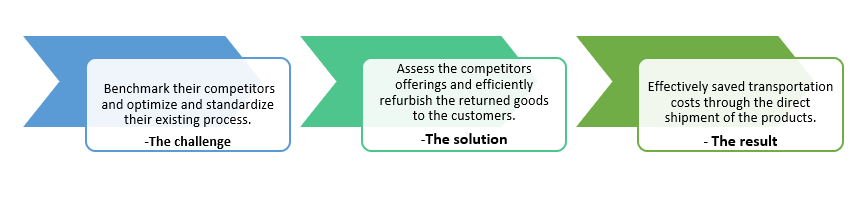

A renowned reverse logistics company wanted to benchmark their competitors and optimize and standardize their existing process. The client wanted to profile their competitors and offer better services to the customers in terms of maintenance and repairs. With the help of Infiniti’s competitive benchmarking solution, the client wanted to streamline their existing process, gain a competitive advantage over competitors, and improve their overall customer base. Moreover, the reverse logistics client also wanted to seek ways to analyze the data on returns and reduce customer complaints and enhance customer retention. Moreover, the client wanted to bring about agility and efficiency in their supply chain process.

Want more information about how our competitive benchmarking solution helped the reverse logistic client?

Benefits of the Competitive Benchmarking Solution

The competitive benchmarking solution offered by Infiniti assisted the client in assessing the competitor’s offerings and devise plans to stay ahead of the competitors. The reverse logistics client also witnessed a gradual improvement in their service offerings and curtailed issues related to packaging. With our help, the client was able to enhance the shelf life of the products and enhance customer satisfaction levels. The engagement also ensured seamless movement of goods while keeping account of the environmental laws and concerns. The solution further helped the reverse logistics firm to precisely measure the recoverable value of the products and maximize the value of returned goods.

Additional Benefits Offered by Infiniti Include:

- Effectively saved transportation costs through the direct shipment of the products

- Eliminated the need for the initial transfer of products to the warehouses

- Improved the prevailing business operations and enhanced the business revenue